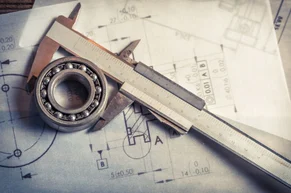

At Emerson Bearing, we know just how vital it is to select the appropriate bearing for each specific application. Ensuring the longevity of your bearing starts with understanding the factors that contribute to wear—and addressing them proactively.

Extending the lifespan of a bearing often involves making adjustments to mitigate common wear issues. Here are some key considerations:

- **High Speeds**: When a bearing operates beyond its recommended speed range, it risks premature wear and failure. This wear is exacerbated by vibrations and unbalanced forces, which can damage the guiding faces of the cage and disrupt smooth operation. To counteract this, ensure proper lubrication of the guiding faces and adjust the load on the bearing if it’s lightly loaded at high speeds.

- **Sudden Changes in Speed**: Accelerating or decelerating too quickly can lead to significant wear due to slippage between the rolling elements and the raceways. To prevent this, consider using bearings with smaller cross-sections, lighter materials for the cage (like plastics or lightweight metals), or preloading the bearing axially.

- **Lubrication and Maintenance**: Lubrication is critical to maintaining bearing health, but even the best lubricants degrade over time due to age, environmental factors, and mechanical stress. While regular relubrication can extend the bearing's life, it might not always be cost-effective depending on the application.

- **Seals**: Proper sealing is another way to protect bearings. Selecting the right seals and grease can keep contaminants like dust and debris from interfering with the bearing’s performance, thus extending its service life.

- **Operational Safety and Monitoring**: Many bearings wear out before the machines they're installed in. Regular inspections can prevent unexpected failures, ensuring operational continuity. The frequency of these checks depends on the bearing's load capacity.

At Emerson Bearing, we’re committed to helping you maximize your bearing’s lifespan. Our Bearing Failure Analysis page offers insights into common causes of bearing failure and actionable steps to address them. Whether you’re looking to optimize existing setups or need guidance on new installations, we’re here to assist. Explore our catalog or reach out to us today!

---

If you’d like more detailed guidance, feel free to download our [Bearing Failure Analysis Guide](http://bsg-i.nbxc.com/blog/e8948c875d364dc012688d2bd1538a18.png). It’s a comprehensive resource designed to help you troubleshoot and resolve common issues effectively. Let us support you in keeping your machinery running smoothly and efficiently!

Gearbox

The hard gear surface transmission device of SZ series manufactured srictly according to the standard of JB/ T9095.1- 1999 consists of reducer

and distributor. It is the special-purpose product of the conical twin screw extruder.

1. The gear of the reducer is high strength alloy steel, carburizing steel. Processed by carburization, quenching and gear grinding, the gear can reach

6-grade.The gear enjoys both high hardness with HRC58-62 and low noise when operating.

2. The gearbox' s small cone angle of helical gear is made by high quality alloy steel. After grinding by CNC gear hobbing machine, the gear will be

carburized, quenched to make sure high precision and hardness.

3. Ductile cast iron case and high strength aligning thrust roller bearings makes the item perform steadily and bear large axial thrust.

4. Equipped with cooling system,the reducer and distributor can run safety.

5. Exquisite craftsmanship of cutting makes the item in great shape. Our factory can also design according to customers' requirements besides our

available specification

Reducer For Plastic Machines,Gearbox For Plastic Machines,Extruder Reduction Gearbox,Sz Series Of Gearbox

Zhoushan Taisu Overseas Co Ltd. , https://www.taisuoverseas.com