Unleashing the Potential of NDT Inspections in Power Generation with Elios 3

VZÚ Plzeň, a leading provider of robotic inspection services, is revolutionizing the way power generation facilities in the Czech Republic are inspected. By leveraging the advanced capabilities of the Elios 3, they are enhancing safety, efficiency, and accuracy across a wide range of industrial assets.

Key Benefits at a Glance

|

Safety First With the Elios 3, VZÚ Plzeň can now conduct inspections in hazardous environments without putting human inspectors at risk. From heights to confined spaces, the drone allows them to access hard-to-reach areas safely, eliminating the need for scaffolding or rope access teams. |

Boosting Efficiency By deploying the Elios 3, VZÚ Plzeň managed to inspect 16,000 points of interest at a cooling tower in just ten days. This rapid turnaround allowed them to complete inspections during scheduled downtimes, minimizing disruptions and ensuring timely delivery of actionable insights. |

|

Pinpoint Accuracy Even when dealing with towering structures like cooling towers exceeding 100 meters in height, the Elios 3 ensures precise localization of data. This level of detail enables inspectors to accurately identify and locate points of interest, streamlining maintenance processes. |

Driving Business Growth By incorporating drones into their NDT workflows, VZÚ Plzeň has attracted new clients and expanded their project portfolio. Their commitment to delivering high-quality data has set them apart from competitors, offering unparalleled value to their clients. |

Understanding Non-Destructive Testing (NDT)

Non-Destructive Testing (NDT) refers to techniques used to examine materials or components without causing any damage. It encompasses a broad spectrum of methodologies aimed at gathering critical information about the condition of assets. One of the core principles of NDT is providing asset managers with accurate data to facilitate informed decision-making and preventive maintenance strategies.

NDT plays a crucial role across diverse sectors such as mining, infrastructure, utilities, cement production, and power generation. Its application helps ensure the longevity and reliability of critical assets, preventing failures and accidents. For the power generation industry, where even minor interruptions can lead to significant financial losses, NDT is indispensable.

Transforming Inspection Practices at Power Plants

VZÚ Plzeň offers a comprehensive suite of NDT solutions tailored specifically for power generation facilities in the Czech Republic. Embracing cutting-edge robotic technologies, they continuously refine their inspection processes to maintain a competitive edge. After participating in a Flyability training program in Lausanne, they began utilizing the Elios 2 drone for aerial and confined space inspections in late 2022. Since upgrading to the Elios 3, the team has experienced remarkable improvements in piloting, data collection, and overall operational efficiency.

Initially, professionals within the power generation sector expressed skepticism regarding drones' utility for inspections. However, VZÚ Plzeň's consistent demonstration of the Elios 3's capabilities—highlighting substantial cost and time savings alongside enhanced safety measures—has won over skeptical stakeholders. Their reputation among clients has flourished as a result.

Drone inspector Filip Schmidt noted, "The Elios 3 has transformed our approach to indoor inspections across various power generation settings." Today, VZÚ Plzeň's inspection portfolio includes boilers, evaporators, burners, superheaters, cyclones, air ejectors, flue gas tubing, cooling towers, steam turbine condensers, desulfurization equipment, piping hangers, vessels, wind turbines, and much more.

Streamlining Boiler Inspections with the Elios 3

Traditional boiler inspections often necessitate the installation of scaffolding, resulting in extended asset downtime and increased safety risks. Even prior to determining whether maintenance is required, these preparations must be made. In contrast, an aerial inspection using the Elios 3 can yield comprehensive visual and LiDAR data about the boiler's condition within hours, all without scaffolding or exposing personnel to danger. If no maintenance is needed, the plant avoids unnecessary expenses related to scaffolding, labor, and equipment rental. Should intervention be necessary, the Elios 3 provides precise defect localization, allowing teams to focus their efforts where they're truly needed, thereby reducing downtime and boosting productivity.

This boiler inspection was conducted using the Elios 3 to access the asset internally.

Such inspections enable VZÚ Plzeň to gather essential data while keeping teams safe and operational disruptions to a minimum. Boilers at power plants generate hundreds of megawatts of electricity; any unplanned downtime or prolonged maintenance can severely impact energy supply and incur significant revenue losses. Therefore, employing the Elios 3 for boiler inspections enhances planning efficiency and minimizes risks associated with traditional methods.

Validating Flue Duct Conditions via Drones

One particular challenge faced by VZÚ Plzeň involved assessing the integrity of flue gas ductwork. These systems frequently suffer from wear due to abrasive ash particles traveling through the pipes. At one facility, engineers installed steel guide plates intended to shield against structural degradation. Despite this precautionary measure, the plates had worn down significantly, creating hazardous conditions unsuitable for rope access inspections. Fortunately, the Elios 3 offered a safe and effective alternative.

The Elios 3 allows for remote inspections of assets at height from ground-level positions.

During the mission, VZÚ Plzeň's pilots discovered severe erosion in certain sections of the steel supports, posing a threat to the ductwork's structural integrity. Thanks to the Elios drone, they delivered valuable insights while maintaining operator safety and avoiding costly manual interventions.

Performing 300 Flights Inside a Power Plant Cooling Tower

In early 2023, VZÚ Plzeň received a request to inspect the cooling towers of a power plant. Over two visits within four months, coinciding with planned maintenance windows, they executed what became the first-ever aerial inspection of its kind at the site. Although initially skeptical, plant managers soon recognized the immense potential of drone technology.

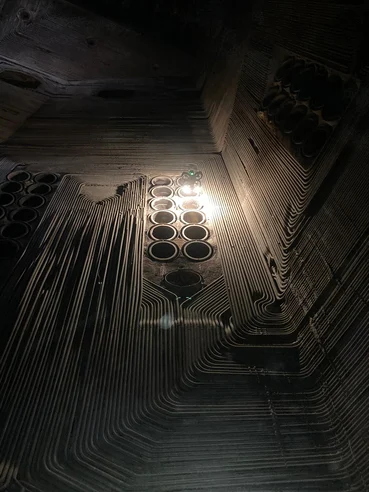

The bases of the cooling towers contained numerous structures examined using the Elios 3.

Over ten days, VZÚ Plzeň completed approximately 300 flights, examining around 16,000 points across four cooling towers. Given the vast scale of the operation, processing the collected data meticulously was paramount. Each defect was pinpointed and documented alongside corresponding geographical coordinates and severity ratings. This level of precision greatly benefited the plant managers, who gained clear visualizations and detailed reports highlighting issues identified by VZÚ Plzeň's experts.

Building Trust in Drone-Based Inspections

VZÚ Plzeň's success stories in applying drone inspections to power generation underscore the transformative impact of this technology. By reducing reliance on expensive scaffolding and improving workplace safety, they've set new standards in the industry.

Speaking with Flyability, Filip Schmidt emphasized the profound influence drones have had on VZÚ Plzeň's operations: "Our transition into drone-based inspections hasn't just modernized our offerings; it has reshaped how both we and our clients view safety and operational efficiency. As we delve deeper into opportunities within the power generation domain, we remain steadfast in our dedication to delivering superior outcomes in every engagement."

Currently operating throughout the Czech Republic, VZÚ Plzeň continues to demonstrate how drones can deliver tangible benefits such as enhanced inspection safety, reduced downtime, and elimination of costly scaffolding requirements. Looking ahead, they anticipate further expanding their service reach where the Elios drones' accessibility advantages promise even greater speed and security in future missions.

Learn more about the Elios 3 and its diverse applications.

High Carbon Steel Strip,High Carbon Alloy Steel Strips,Cold Rolled Steel Strips,Cold Rolled Steel Sheet And Strip

Jiangyin Mitoo Precise Co.,Ltd. , https://www.mitoosteel.com