As the name suggests, short radius elbows are considerably smaller in size compared to their long-radius counterparts. These elbows feature a bend radius that matches the diameter of the pipe, making them ideal for situations where space is limited. Due to their unique design, they are typically used for low-pressure fluid applications and are rarely found in high-pressure pipeline systems.

Table of Contents

- Specification of SR Elbows

- Dimensions of 90 Degree Short Radius Elbows

- 45 Degree SR Elbow Dimensions

- ASME B16.9 Short Radius Elbow Dimensions in Inches

- Formula for Calculating Short Radius Elbows

- Applications of SS Short Radius Elbows

- Comparison: Long Radius vs Short Radius Elbows

- Weight Chart for 90 Degree Short Radius Elbows

- Types of Short Radius Elbows

- Tolerances for Inconel Buttweld SR Elbows

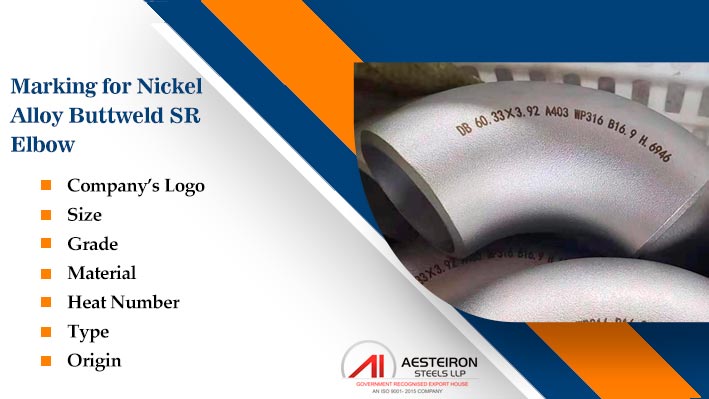

- Marking on Nickel Alloy Buttweld SR Elbows

- Materials and Grades for ANSI B16.9 SR Elbow Fittings

Manufacturer of ASME B16.9 Short Radius Elbows in India

ASME B16.9 short radius elbows are commonly produced with a 90-degree angle, providing a much sharper turn than long radius elbows. These fittings are manufactured under the guidelines of the American Society of Mechanical Engineers (ASME), which ensures strict quality control over aspects like pressure rating, marking, dimensions, surface finish, tolerances, and testing procedures.

Adhering to the ASME B16.9 standards guarantees reliable performance and durability of the pipe fittings.

Specifications of SR Elbows

| Short Radius Elbow Size |

|

|---|---|

| Manufacturing Type of ASME B16.9 Short Radius Elbows |

|

| Thickness |

|

| Dimension Standards |

|

| Type |

|

| Material for 45 Degree SR Elbows |

|

| Certificates for 3/8 NPT Street Elbows |

|

| Origin of 3/4 Street Elbows |

|

| Pressure Class for 45 Degree SR Elbows |

|

| Connection Type |

|

| Standards for Short Radius Elbows |

|

| Manufacturing Methods |

|

| Thickness Tolerance |

|

| Testing of 90 Degree SR Elbows |

|

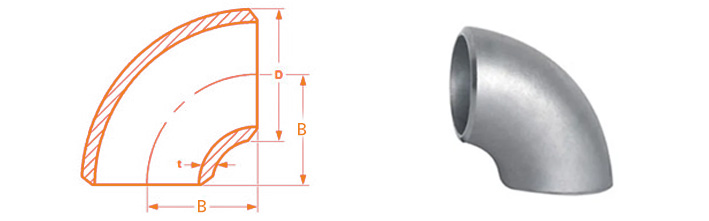

Dimensions of 90 Degree Short Radius Elbows

| NPS in Inches | Center to End B |

Outer Diameter D |

|---|---|---|

| 1 | 25 | 33.4 |

| 1¼ | 32 | 42.2 |

| 1½ | 38 | 48.3 |

| 2 | 51 | 60.3 |

| 2½ | 64 | 73 |

| 3 | 76 | 88.9 |

| 3½ | 89 | 101.6 |

| 4 | 102 | 114.3 |

| 5 | 127 | 141.3 |

| 6 | 152 | 168.3 |

| 8 | 203 | 219.1 |

| 10 | 254 | 273 |

| 12 | 305 | 323.8 |

| 14 | 356 | 355.6 |

| 16 | 406 | 406.4 |

| 18 | 457 | 457 |

| 20 | 508 | 508 |

| 22 | 559 | 559 |

| 24 | 610 | 610 |

Short Radius Reducing Elbows are Manufactured in Sizes Ranging from 1/2 to 48 Inches

The extensive size range of short radius reducing elbows facilitates seamless connections between different pipe diameters within a piping system. They ensure efficient fluid flow by minimizing restrictions and allowing precise transitions between various pipe sizes used in plumbing and industrial applications.

The following table provides the dimensional specifications of short radius elbows:

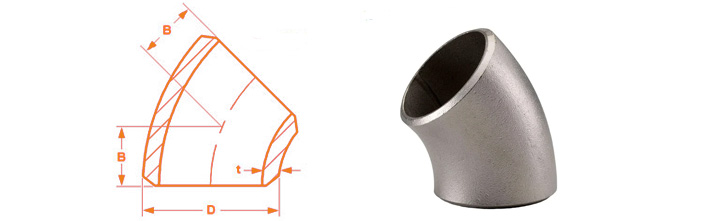

Dimensions of 45 Degree SR Elbows

| NPS in Inches | Outer Diameter D |

45° 3D Center to End A |

45° SR Center to End A |

|---|---|---|---|

| 1/2 | 21.3 | – | 38 |

| 1 | 33.4 | 76 | 38 |

| 1½ | 48.3 | 114 | 57 |

| 2 | 60.3 | 152 | 76 |

| 3 | 88.9 | 229 | 114 |

| 4 | 114.3 | 305 | 152 |

| 6 | 168.3 | 457 | 229 |

| 10 | 273 | 762 | 381 |

| 14 | 355.6 | 1067 | 533 |

| 18 | 457 | 1372 | 686 |

| 22 | 559 | 1676 | 838 |

| 26 | 660 | 1981 | 991 |

| 30 | 762 | 2286 | 1143 |

| 34 | 864 | 2591 | 1295 |

| 38 | 965 | 2896 | 1448 |

| 42 | 1067 | 3200 | 1600 |

| 44 | 1118 | 3353 | 1676 |

| 46 | 1168 | 3505 | 1753 |

| 48 | 1219 | 3658 | 1829 |

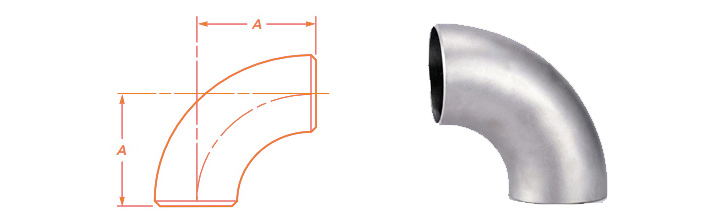

ASME B16.9 Short Radius Elbow Dimensions in Inches

| Nominal Size | OD at Bevel | Center to End |

|---|---|---|

| in. | A

in. |

|

| 1 | 1.32 | 1 |

| 1 1/4 | 1.66 | 1.25 |

| 1 1/2 | 1.90 | 1.50 |

| 2 | 2.38 | 2 |

| 2 1/2 | 2.88 | 2.50 |

| 3 | 3.50 | 3 |

| 3 1/2 | 4 | 3.50 |

| 4 | 4.50 | 4 |

| 5 | 5.56 | 5 |

| 6 | 6.62 | 6 |

| 8 | 8.62 | 8 |

| 10 | 10.75 | 10 |

| 12 | 12.75 | 12 |

| 14 | 14 | 14 |

| 16 | 16 | 16 |

| 18 | 18 | 18 |

| 20 | 20 | 20 |

| 22 | 22 | 22 |

| 24 | 24 | 24 |

In short radius elbows, the radius equals the pipe diameter (R=D).

This characteristic allows for a more compact bend that facilitates smoother fluid flow redirection in piping systems. By maintaining the same radius, these elbows reduce the need for additional components and ensure uninterrupted flow between connected pipes.

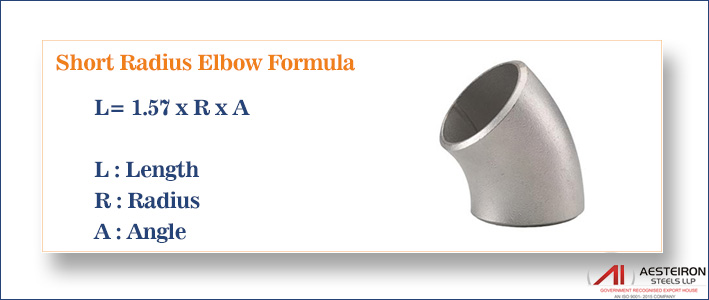

Formula for Calculating Short Radius Elbows

90-degree short radius elbows are commonly used in situations where sharp corners are necessary.

Their compact design enables them to fit into tight spaces and accommodate rapid directional changes in piping layouts. This results in shorter overall piping runs, making them suitable for confined installations.

Applications of SS Short Radius Elbows

- Oil and Gas Pipelines

- Water Supply Systems

- Chemical Industry

- Power Plants

- Industrial Fabrication

- Structural Piping

- Paper and Pulp Industry

- Food Processing Industry

45-degree short radius elbows cause higher pressure drops compared to long radius elbows.

Due to increased turbulence, they are not as commonly used as long radius elbows. However, they find application in scenarios where flow rate is less critical, such as long-distance fluid transport or multiple directional changes. Additionally, they are employed in installations requiring powerful pumping equipment.

Comparison: Long Radius vs Short Radius Elbows

| Description | Long Radius | Short Radius Elbow |

|---|---|---|

| Size | 1.5 times greater diameter | Same as pipe diameter |

| Bend Radius | Larger | Smaller |

| Shape | Flatter | Sharper |

| Appearance | Curved curve | Sharper curve |

| Flow Resistance | Lower resistance | Higher resistance |

| Fluid Flow Effects | Smooth flow | Turbulent flow |

| Applications | Chemical and Oil/Gas Industries | Where turbulence is acceptable |

| Advantages | Heavier than short radius | Lighter than long radius |

| Cost | More expensive than short radius | Less expensive than long radius |

| Pressure Loss | Higher | Lower |

Weight Chart for 90-Degree Short Radius Elbows

| NPS | Weight in Kilograms |

|---|---|

| 1/2 | .08 |

| 1 | .18 |

| 1 1/2 | .41 |

| 2 | .73 |

| 3 | 2.27 |

| 4 | 4.08 |

| 6 | 11.11 |

| 10 | 39.92 |

| 14 | 72.57 |

| 18 | 117.93 |

| 22 | 178.72 |

| 26 | 249.48 |

| 36 | 481.72 |

Types of Short Radius Elbows

Short Radius 90-Degree Elbow

45-Degree SR Elbow

3D Short Radius Elbows

ASME B16.9 5D Short Radius Elbow

Buttweld Short Radius Pipe Elbow

1.5D Schedule 10 SR Elbows

Tolerances for Inconel Buttweld SR Elbows

| NPS | 32 to 48 | 26 to 30 | 20 to 24 | 10 to 18 |

|---|---|---|---|---|

| OD at Bevel (D) | + 6.4 – 4.8 |

+ 6.4 – 4.8 |

+ 6.4 – 4.8 |

+ 4 – 3.2 |

| ID at End | 4.8 | 3.2 | ||

| Center to End 3D (A/B) | 6 | 6 | 3 | 3 |

| Center to End LR (A/B) | 5 | 3 | 2 | 2 |

| NPS | 5 to 8 | 4 | 3 to 3.1/2 | 1/2 to 2.1/2 |

| OD at Bevel (D) | + 2.4 – 1.6 |

1.6 | 1.6 | + 1.6 – .8 |

| ID at End | 1.6 | .8 | ||

| Center to End 3D (A/B) | 3 | 3 | 3 | 3 |

| Center to End LR (A/B) | 2 | 2 | 2 | 2 |

Marking for Nickel Alloy Buttweld SR Elbows

Materials and Grades for ANSI B16.9 SR Elbow Fittings

| Material | Standards and Grade |

|---|---|

| Carbon Steel Short Radius Elbow |

|

| Alloy Steel Short Radius Elbow |

|

| Stainless Steel Short Radius Elbow |

|

| Inconel 90-Degree Short Radius Pipe Elbow |

|

| Copper Nickel Short Radius 90-Degree Elbow |

|

| Hastelloy Short Radius Reducing Elbow |

|

| Nickel Alloy SR Elbow |

|

| Duplex Short Radius Elbow |

|

| Super Duplex SR 45-Degree Elbow |

|

| Incoloy SR Elbow |

|

| Titanium Short Radius 90-Degree Elbows |

|