Products Features

Vibration intensity can be adjustable based on air pressure, can immediately start, stop, fast, low-noise, vibration force, security.Â

Application

Feed material conveyor, vibrating screening, vibrating hopper, to help fill packing, foundry sand mold vibration.

Works

Copper eccentric gear installed counterweight impact air intake charge into the gear rotates, the eccentric rotation of the centrifugal weight with vibration, the gear driven by a bearing, low noise.

Â

| Type | Frequency(V.P.M) | Vibration Power(N) | Air Consumption(L/min) | Weight(kg) | ||||||

| 0.2Mpa | 0.4Mpa | 0.6Mpa | 0.2Mpa | 0.4Mpa | 0.6Mpa | 0.2Mpa | 0.4Mpa | 0.6Mpa | ||

| GT-4 | 11.500Â | 12.500Â | 13.500Â | 130 | 165 | 210 | 30 | 40 | 50 | 0.28 |

| GT-6 | 11.500Â | 12.500Â | 13.500Â | 130 | 165 | 210 | 30 | 40 | 50 | 0.28 |

| GT-8 | 34.850Â | 42.000Â | 45.500Â | 980 | 2.100Â | 2.800Â | 46 | 80 | 112 | 0.28 |

| GT-10 | 27.500Â | 35.000Â | 37.500Â | 840 | 1.390Â | 2.400Â | 46 | 80 | 112 | 0.28 |

| GT-13 | 26.000Â | 30.000Â | 33.000Â | 1.400Â | 2.440Â | 3.730Â | 120 | 200 | 290 | 0.61 |

| GT-16 | 17.000Â | 21.500Â | 24.000Â | 1.220Â | 2.090Â | 3.160Â | 120 | 200 | 290 | 0.61 |

| GT-20 | 17.000Â | 20.000Â | 23.000Â | 2.170Â | 4.040Â | 5.520Â | 185 | 325 | 455 | 1.12 |

| GT-25 | 12.000Â | 15.500Â | 17.000Â | 2.120Â | 3.510Â | 5.070Â | 185 | 325 | 455 | 1.12 |

| GT-32 | 13.000Â | 14.000Â | 16.000Â | 3.380Â | 5.430Â | 7.540Â | 330 | 530 | 745 | 2.15 |

| GT-36 | 7.800Â | 10.000Â | 13.000Â | 3.300Â | 5.000Â | 7.150Â | 330 | 530 | 745 | 2.15 |

| GT-40 | 7.500Â | 8.800Â | 9.500Â | 4.350Â | 7.350Â | 9.850Â | 408 | 428 | 680 | 3.53 |

| GT-48 | 5.800Â | 7.500Â | 9.700Â | 4.950Â | 7.750Â | 10.6007Â | 408 | 428 | 680 | 3.53 |

| GT-60 | 4.758Â | 6.530Â | 8.515Â | 5.700Â | 9.800Â | 11.150Â | 505 | 600 | 920 | 5.59 |

We specialize in pneumatic parts field for several years, with best quality and best service with competitive price.Our advantages:

1. Passed ISO9001. 2. Sell at competitive factory price. 3. A one-year warranty(All Products). 4. Perfect management and excellent product quality. 5. Do the inspection for all the products before delivery.Â

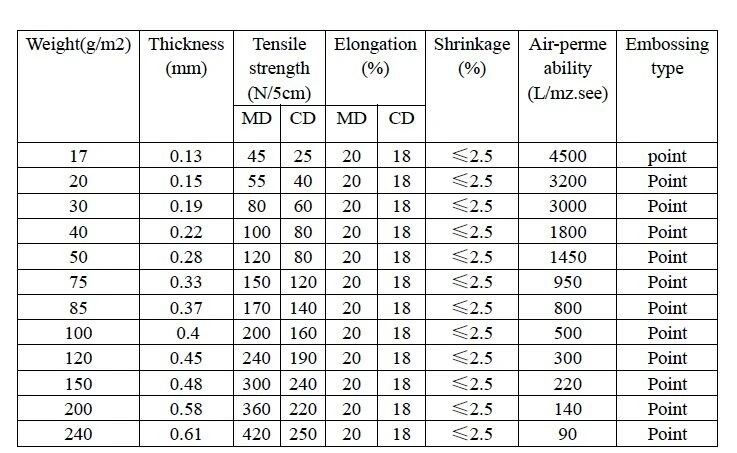

Non Woven Fabric

FY-hengfa nonwoven Fabric series: PET Polyester Spunbond Non woven, Meltblown Nonwoven, Activated Carbon Nonwoven Fabric, Nonwoven Filter Bag,Nonwoven Fabric For Auto Filter.

Such as:

100% PET/PP spunbond nonwoven fabric.

It is similar to filament yarn production. From the chips storage, the polymer is vacuum-fed to a dosing station on top of the extruder. Inside the extruder, it becomes melted and homogenized. Passing a filter system and a spin pump, the melt is fed into the spin beam or spinnerets, which form a curtain of filaments. The filaments are cooled by means of a stream of air in a blowing area, drawn by aerodynamic forces and then transported to the downstream discharge channel. For nonwovens, instead of a further stretching process for filament yarns, the filaments are swirled around and then deposited on the wire mesh belt as a random nonwoven. This web is transferred to a bonding calender that uses heat and pressure to set such physical properties as tensile strength and elongation of the final product. After cooling, the material can be wound.

Product :Spun-bonded Nonwoven

Material :100% polyester

Width :0.15-3.20m.

Specification:1000M-4500M/roll or customized

Weight :10gsm-260gsm

Use :

1. Medical : face mask ,surgical cloth ,bedsheet ,disposable cap , shoose cover .

2. Packing : shopping bag , tablecloth ,wallpaper ,compund packing material .

3. home textile : pillow case ,mattress cover ,linling .

4. Industry : protect the crop from insect .cold weather .filtration materials

Non Woven Fabric

Non Woven Fabric,Pet Non Woven Fabric,Activated Carbon Nonwoven Fabric

Hebei Fangyu Trade Co., Ltd. , https://www.filtersmaterial.com